color case hardening temperature

I have been successful color hardening by placing the parts in a capped 4 inch pipe in a charcoal fire for several hours. From the earliest guns that were.

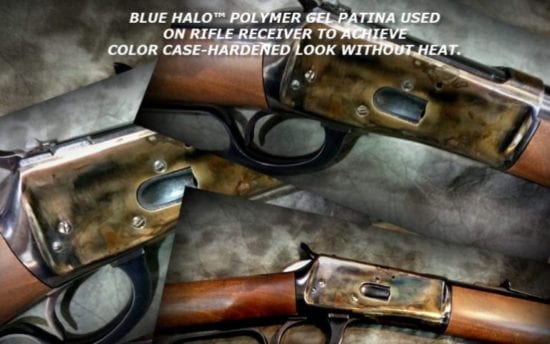

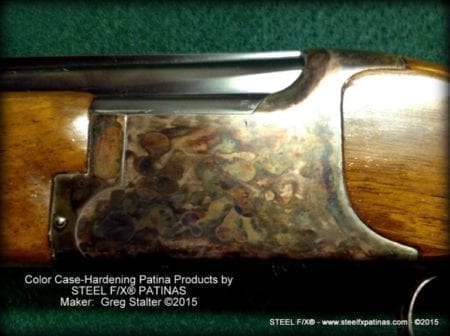

Color Case Hardening Patina Kit

Case Hardening Alone Leaves A Dull Gray Finish Think Mill Files Unless Additives Are Added To Produce Color.

. Bone charcoal case hardening takes a good deal of. Ad Solve Your Thermal Processing Challenges. To achieve these results we use the traditional method of packing the component into a steel crucible together with a generous amount of charred bone wood and leather then heating the.

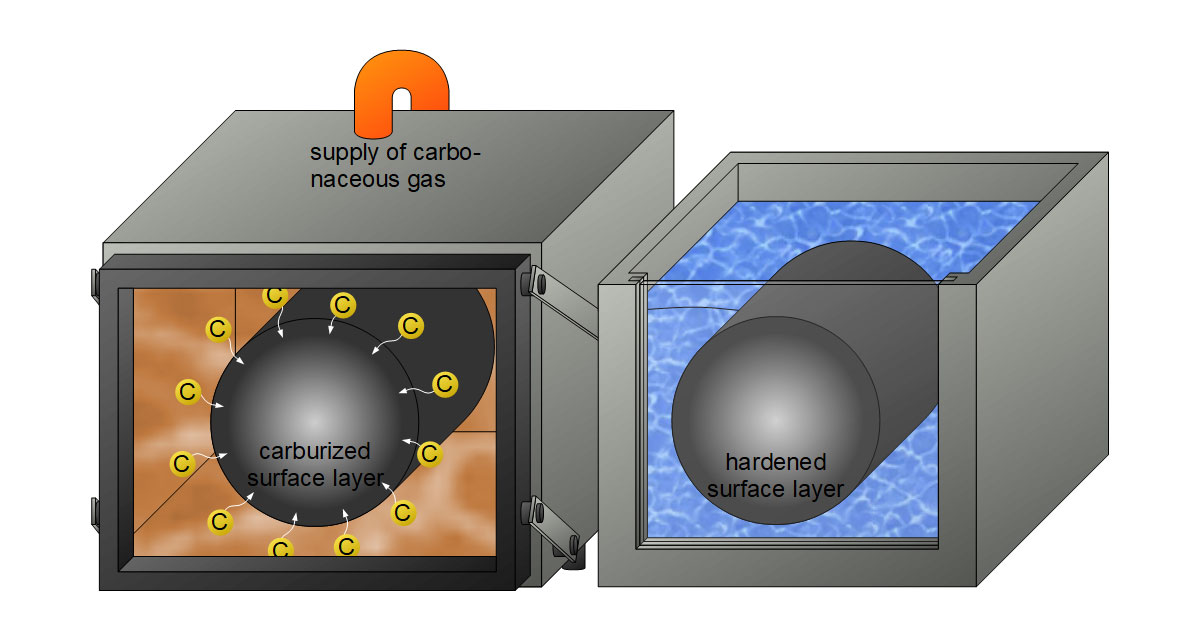

COLOR CASING Here at Tyler Gun Works we are able to Color Case items others cant due to our ability to work at lower temps. In a nutshell color case hardening is basically carburizing adding carbon to the surface of the steel and hardening steel. Leave the canister in the oven until it returns to room temperature.

Improve The Wear Properties Of Your Parts With Vacuum Carburizing. However if the parts have previously been color case hardened he first anneals them in wood charcoal heated to 1375 degrees Fahrenheit for a half hour. Heat the kiln to 1350 degrees and hold it there for two hours then reduce the temperature to 1100 for one hour.

He feels it gives a better surface. Improve The Wear Properties Of Your Parts With Vacuum Carburizing. Advanced Expertise And World-Class Equipment.

Kasenit and similar compounds are a lot easier to use. Advanced Expertise And World-Class Equipment. Place in the heat treat oven and bring to 1500 F.

It also happens that a side effect of this process is the production of those oh-so-coveted case colors we are so fond of. Case hardening was used into the 1900s for parts. Contact Brownells and ask for their instructions for color case hardening.

Ad Solve Your Thermal Processing Challenges. Hold at that temperature for one hour then turn off the heat. You have to watch the temperature more closely with color case hardening or the colors wont come out well.

It is heated to somewhere around 1200 to 1400 degrees and then quenched. We keep our temperatures below hardening temperatures. Dont go over 1350 F.

The 104045 grade can go either way on heat treatment and is not generally not case harden. Wyoming Armory is a custom gunsmithing shop where we build custom firearms but one of our specialities is tradional bone charcoal color case hardening. As for the difference in the three they are all the same process of case hardening.

Color Case Hardening Patina Kit

Color Case Hardening Turnbull Restoration

Color Case Hardening Turnbull Restoration

How To Do Color Case Hardening The Hobby Machinist

American Handgunner When You Re Hot American Handgunner

American Handgunner When You Re Hot American Handgunner

Color Case Hardening Turnbull Restoration

How To Color Case Harden Presented By Larry Potterfield Midwayusa Gunsmithing Youtube

Color Case Hardening Shooting Sportsman Magazine

Color Case Hardening Turnbull Restoration

Color Case Hardening Turnbull Restoration

The History Of Case Hardening And Its Processes Double Stone Steel

Guns Magazine Case Hardening Redux Guns Magazine

Color Case Hardening Patina Kit

Color Case Hardening Turnbull Restoration

American Handgunner When You Re Hot American Handgunner

Is Case Hardening Supposed To Uh Come Off R Guns